Advantages Of Lightweight Robotic Arms

Robotic arms are an integral part of automation with robots. They have been in the factory floor for the longest time ever. Traditional robot arms were heavy steel made arms that worked well caged away from the rest of the factory floor.

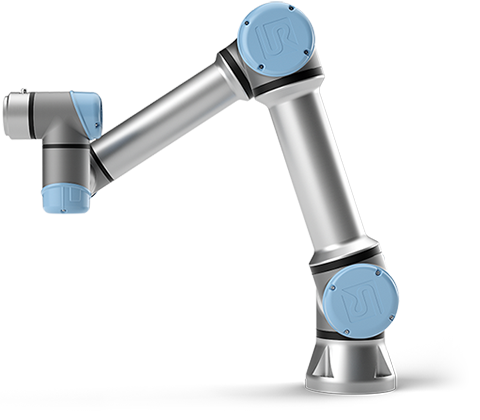

Many years later, the heavy and intimidating robotic arm has been replaced by a modern lightweight arm that is easy to use and highly collaborative.

Advantages of lightweight robotic arms

Highly collaborative

Lightweight robotic arms are an integral part of the growing trend of collaborative robots. Since they work in close proximity with the human colleagues, they need to be safe for better interaction within the factory floor.

Since they are made with lightweight material rather than the heavy steel of the traditional robots, they cause less to no injuries to those who work around them in the case of an accidental brush up against them.

Enhanced flexibility

From the Universal Robots stable, the UR5 is one of the highest selling lightweight flexible robot arm. Many manufacturing entities have acquired it for a specific purpose and found it quite useful in an extensive range of tasks within the factory.

All it requires is a fitted end of arm attachment and the robot changes from one task to another with ease.

This robot arm can be assigned tasks such as welding, painting, assembling and pick and place.

Affordable

Lightweight robotic arms compared to the traditional robots are price friendly and easily accessible by any firm regardless of their size.

Besides its friendly price, the investment to purchase one is recouped quickly. For most firms 18 months is the longest it took for them to have earned their money back from the investment in the robot.

Lower production costs

Lightweight robots help organizations lower their operating costs. Speed is the main method with which they accomplish this. Robots work faster than any team of manual laborers. As a result, the use of the robots leads to increased production at lower costs.

Second, robots are highly accurate and precise. As a result, there is reduced waste in the production process. This helps the manufacturing costs considerably lower their costs of production as there is more effective use of available resources.

Easy to use

Modern flexible robotic arms are easy to use. They do not require the factory to hire specialized programmers. Their user interface is quite easy to understand that a child who can use a smart phone can easily operate the robot.

Instructions are programmed easily into the robot. In addition, the underlying technology allows for the robot to be instructed manually by moving its arms in the way that it should while completing a task. It will record this movement and will follow the exact instructions when it starts working.

Additionally, robot manufacturers such as Universal Robots offer free certified courses to teach the users of their robots how to use them more effectively.

Keep up with technology

Lightweight robotic arms are built with modern technology for the current factory and for that of the future. Through machine learning and easy access to the internet, modern robotic arms can learn how to complete various tasks on their own.

In addition, the robots can easily collaborate with human workers and other robots.

Through technology, these robot arms are much safer around human beings. They have sensors that can tell them how close a human being is which enable them to shut down or slow down the process to make it safe for the human to be close to them.

Compact size

Lightweight robotic arms are quite compact. The UR5 for example has a base diameter of 149 mm and a reach of up to 33.5 inches.

This allows the factory to save up on space. Lower lease payments go a long way in the reduction of production costs. Their small size also ensures that they can be set up anywhere in the factory to assist in completing different tasks.